INFO@CSEBM.COM

-

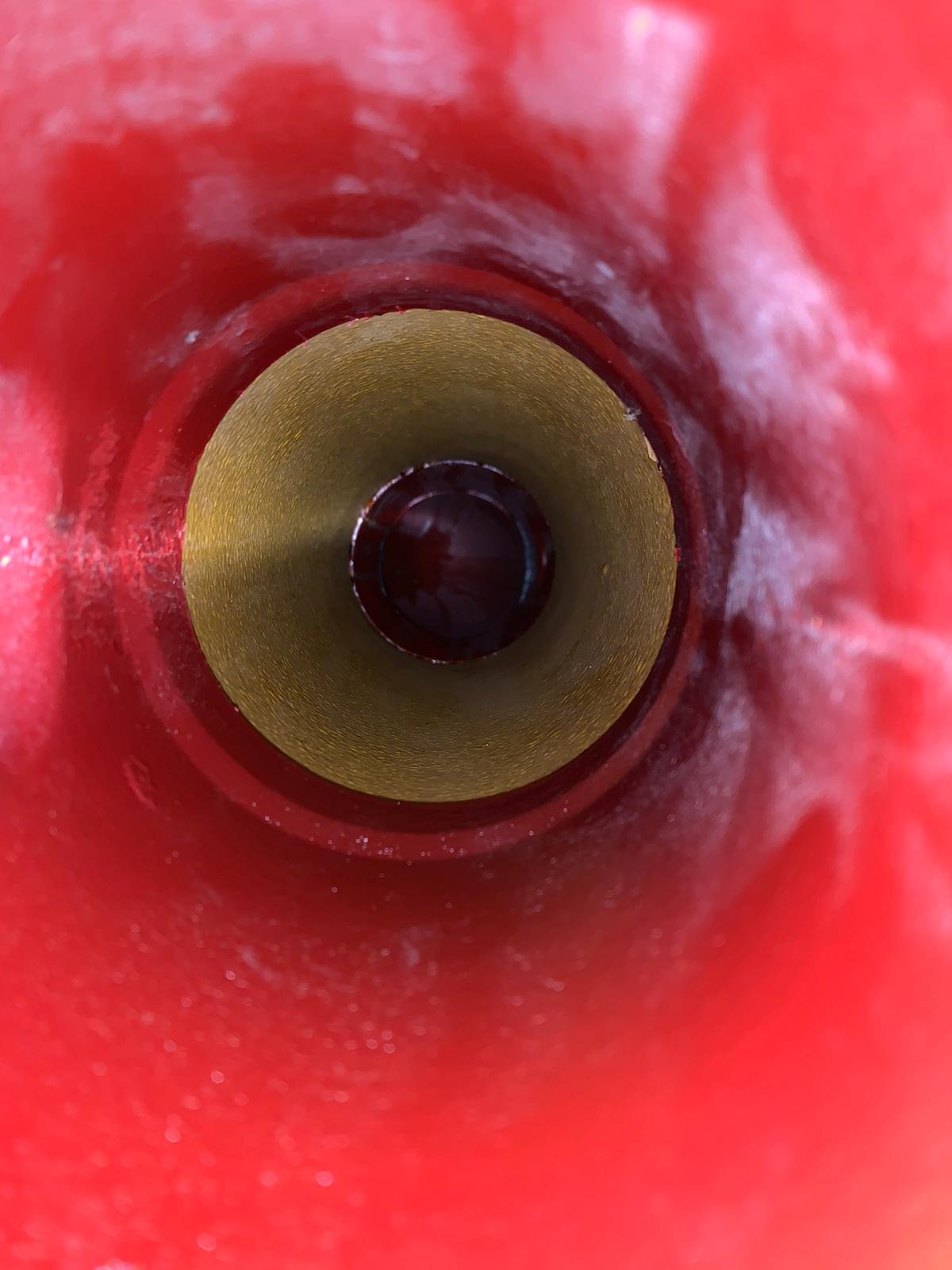

CIPP

CIPP is less disruptive to the environment and the public than the traditional method of excavation.

-

TRENCHLESS REPAIR

CIPP is a form of trenchless repair solution, also known as ‘no-dig’ technology. Commonly CIPP involves insertion of a Resin impregnated reinforced liner through an existing pipeline, the liner

-

THE PROCESS

Once the process approved involves a needle felt or glass fibre liner being impregnated with resin. Using either pinch rollers or a wet out table to ensure the liner is fully saturated. The liner is then installed into the pipe using either an inversion or drag in method.

CIPP RELINING.

CIPP is a form of trenchless repair solution, also known as ‘no-dig’ technology. Commonly CIPP involves insertion of a Resin impregnated reinforced liner through an existing pipeline, the liner is the cured insitu to form a seamless, jointless pipe within an existing pipeline, restoring the strength and serviceability of the pipe without he disruption that would be caused by the traditional method of excavation. CIPP is less disruptive to the environment to the public, and is more economic in almost all cases, than Open Cut Excavation.

CIPP methods can be used to rehabilitate sanitary sewers, storm drains and pressure pipelines for water, gas and process effluents. We are able to accommodate circular pipes from 50mm to 1800mm diameter through our own impregnation facility and to supply liners up to 2700mm diameter, we can also accommodate non circular pipe profiles.

THE PROCESS.

Firstly the materials and process for each job are specified and designed by the contractor with advice from the supplier. Including material choice, liner thickness, installation and curing method.

The pipe is then cleaned and any debris removed. In the case of damage and deformation to the pipe, local repairs may need to be performed, ready for the CIPP process.

Once this has been approved the process involves a needle felt or glass fibre liner being impregnated with resin. Using either pinch rollers or a wet out table to ensure the liner is fully saturated. The liner is then installed into the pipe using either an inversion or drag in method.